ScrOG blOG™ — scrogging

Maximum Yield - SCROGGER Profile

It all started when Gary offered to help solve the issues a friend was having with a DIY screen of green (ScrOG) set-up. Not only was this friend having trouble reaching all of his plants to do the low-stress training necessary for ScrOG, but his friend had “virtually destroyed” the whole set-up trying to solve a problem with one plant.

So, Gary scrapped the bamboo and trellis netting his friend was using and designed an accessible and versatile alternative out of clear polycarbonate. It didn’t take him long after that to recognize that this new design had the potential to fill a niche in the hydroponics market.

“Many want to ScrOG in a more-convenient, less-time-consuming and more effective way,” Gary says. “All of our products provide tremendous convenience to the grower who desires to use plant training techniques.”

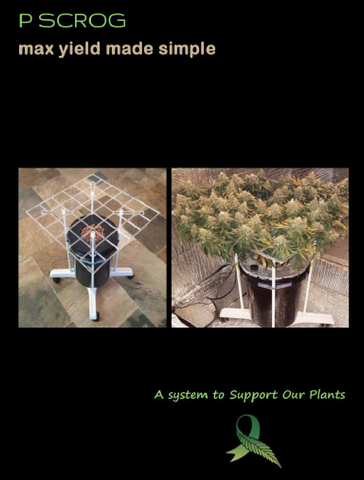

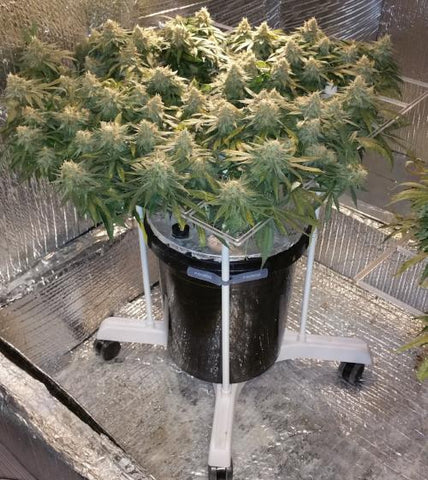

Gary’s design, which is now sold as the P SCROG Primary and the P SCROG Pro, consists of one or two growing screens attached to a base by four supporting rods. The system’s base can accommodate 250 pounds and is wide enough for any container measuring between 10 and 22 inches. The whole thing sits on casters, which is a major selling feature. “Customers are enthusiastic about the benefit of being able to rotate the plant on the casters to trim, spray and care for their plants,” Gary says. “Some of our customers are disbled and can’t reach or lift as well as they used to, so being able to turn the plant is a huge advantage.”

The screens on both P SCROG set-ups are also easily adjusted. Growers can raise or lower each by 12 inches, helping to force horizontal growth and to provide support for swelling buds. As mentioned above, the screens are made from polycarbonate—a tough, flexible material used in bullet-proof glass. “The flexural strength of this plastic is 13,500 PSI,” Margo says. “You should see the look on people’s faces when we flex the screen, they wince, expecting a snap; then they say ‘Wow!’”

In addition to the screens being strong, they are reusable, have a UV inhibitor, are non-porous and are food-grade. They provide a clean, almost clinical look in the growroom and are washable. They can also withstand temperatures far greater than you’d ever experience in the growroom. When they finally do wear out, the screens are 100 per cent recyclable.

To be sure they were bringing a viable product to the masses, the Mermelsteins knew they had to research the market. They had prototypes made in September 2014 and toured hydroponics shops in Phoenix and Denver to gather input from potential customers. As they hoped, the response was incredibly positive. At that point, they were ready to go for it. After incorporating the company in June 2015, they produced CAD drawings, filed a patent for their design and invested in the tooling needed to make plastic injection molded parts. It took nine months of engineering, but it was worth the effort when the first SCROGGER products were sold in January 2016.

“Since we launched the P SCROG, the most common comments we hear were things like, ‘Brilliant,’ or ‘I see how it works, no need to explain,’ or ‘I could really use something like that that,’” shares Gary. Similarly, Margo says they have not had a single customer complaint about the quality or assembly of their products. “Our main components to the P SCROG—the screens, base and junction caps—are molded right here in the USA,” she says. “The system is very well constructed with high-quality materials.”

Recently, the company expanded their lineup to include the P SCROG 4×4. This set-up is designed for growers with large, multiple plants using 4×4 or 4×8 trays and tables. These frames can be daisy chained together for large commercial applications.

In addition to their solid product line, great customer service has been one of the company’s strengths, with seven days a week support just a phone call or email away. “We are always happy to talk to shop owners and growers about the P SCROG,” says Gary.

Today, SCROGGER sells both on the web and in about a dozen hydroponic stores across the US, but they expect that number to grow rapidly. The company also works with a distributor in Canada and has its products in Australia. “We are adding more hydroponic stores every month,” says Margo.

While the Mermelsteins believe the hydroponic market is very different from their prior business experience, they feel the opportunities the industry presents are excellent, and they believe SCROGGER will play an important role in providing convenience and simplicity to growers everywhere.

*Original article published in Maximum Yield

P SCROG Kits

or

SupportOurPlants@SCROGGER.com

- Gary Memelstein

- Tags: growing cannabis hydroponics indoor grow indoor growing P SCROG screens scrog scrog kit scrog kits scrog method scrog net scrogging

Powdery Mildew and Bamboo Stakes

Could cannabis growers be introducing powdery mildew (PM) to their gardens with bamboo stakes? While I don't have a definitive answer, there is a body of anecdotal evidence that suggests it is possible to infect plants with PM transferred by bamboo.

My PM curiosity was triggered by a grower I met at CannaGrowExpo in Denver last month. While chatting about various methods to support plants he asked; Do you ever see PM or mold develop on bamboo just above the surface of the soil?

"Mildew and molds are fungi - simple microscopic organisms that thrive anywhere there is a moist environment. Mildew (mold in early stage) and molds grow on wood products, ceiling tiles, cardboard, wallpaper, carpets, drywall, fabric, plants, foods, insulation, decaying leaves and other organic materials." (FEMA.gov)

Bamboo is known for disease resistance, but it is not exempt from carrying mold and mildew spores. Mold/mildew spores lie dormant in bamboo culms until growth is triggered by moisture and bamboo stakes in soil are constantly exposed to moisture.

"I noticed that a couple of the bags (bamboo) had stakes that were covered in what looked like PM and I tossed them." THCfarmer.com

Most bamboo is shipped in containers from Asia. Containers experience what is known as "cargo sweat" where a tropical damp climate is created in a closed container, setting up ideal conditions to trigger spores. Quite often bamboo stakes arrive at your local store with active mildew growth from the cargo sweat.

Whether the bamboo you use was shipped in a container or was grown in your backyard, it has a high propensity to be a carrier of mildew spores that might transfer to your precious garden. Any grower who has lost their crop to PM would tell you, there is no bamboo cheap enough to risk your garden over.

Virtually all bamboo in any form can carry mold/mildew spores. A grower should weigh the risks of bamboo against other non porous alternatives that might be slightly more expensive, however not prone to fungus infections.

Bamboo banister

Bamboo banister

Bamboo flooring

or

SupportOurPlants@SCROGGER.com

- Gary Memelstein

- Tags: bamboo stakes growing cannabis indoor grow powdery mildew scrog scrog kit scrog method scrogging trellis

Tale of Two Widows

Long before SCROGGER ever sold its first P SCROG, a friend out west by the name of J. Washington was diligently doing trial grows with some prototypes we sent him. "J" catalogued a landmark grow in a 420Magazine grow journal called "Tale of Two Widows".

J is a long time lover of the White Widow strain and has had significant experience growing it hydroponically. However, in his 2015 grow he saw dramatic differences from what he had seen in the past.

Although the two White Widows came from the same batch of seeds, they grew and looked very different.

The final product looked totally different and yielded different as can be seen below.

Read more about the "Tale of Two Widows" at 420Magazine...

P SCROG Kits

or

SupportOurPlants@SCROGGER.com

- Gary Memelstein

- Tags: growing cannabis hydroponics indoor grow low stress training lst scrog scrog kit scrog method scrogging trellis

Best "How to ScrOG" Guides

Sea of Green (SOG) vs Screen of Green (ScrOG)

A great deal of confusion exists regarding the difference between Sea of Green (SOG) vs Screen of Green (ScrOG) methods of growing cannabis. Before I present what I consider to be some of the better "How to ScrOG" Guides, allow me to briefly define the difference between SOG and ScrOG.

- Ease of providing individual plant care - When 2 or more plants are placed under a single ScrOG net, those plants are typically treated the same out of necessity. Growers have trouble getting to plants at the far reaches of the grow. All plants are treated the same despite their strain maturity level or health.

- Simple to move around if necessary - If you need to pull a plant from a grow for any reason, you need to cut the net and remove it, leaving remaining plants unsupported.

- Improved light distribution - Growers can rotate, custom adjust heights, plants grow at different rates and mature a different rates.

- Easy to remove troubled plant from grow space, lowers risk of damage to remaining crop

- Easier to water and flush

- Allows gardener to harvest plants individually at precise maturity

- Eliminates crawling under nets/wire mesh

- Wheel chair / handicap accessibility

- Irrigation equipment accessibility

- A single plant can be scrogged at an optimal time in its growth cycle. Otherwise, only the most aggressive growing plants enjoy the full benefit of Screen of Green.

P SCROG Techniques

P SCROG Kits

or

SupportOurPlants@SCROGGER.com

- Gary Memelstein

- Tags: best how to scrog guides best scrog guides cannabis plant training grow lights growing cannabis how to scrog hydroponics indoor grow lollipopping lst optimal light band intensity scrog scrog kit scrog method scrog product scrog screen scrog technique scrogging topping trellis trellis net

Optimizing Light

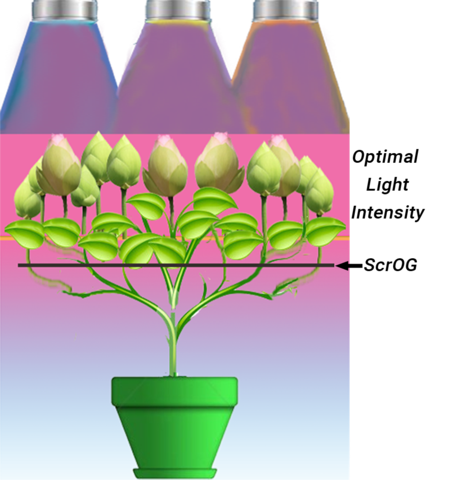

Scrogging builds on the espalier technique to grow short, bushy horizontal plants allowing for maximum bud development. The main stem of the plant is forced to multiply by Topping. Low Stress Training (LST) is accomplished by bending the branches of stems under the lower training screen resulting in more bud development per branch. Lollipopping all leaves of lower branches focuses the energy upward to bud development. A flat horizontal plane of buds, developing all in unison, can be placed in the optimal light intensity band at the same time. No buds are stunted due to upper growth shading and all plant energy is focused solely on bud development.

P SCROG Kits

or

SupportOurPlants@SCROGGER.com

The Denver Defoliator

Mike didn't seem like the abusive type when I first met him at Indo Expo in Denver. ...until he showed me what he does to his plants!!

It takes about 3 days for the untouched little leaves to sprout out and create a full canopy again. I was told that this is merely because of the plant's need for photosynthesis and a need for a leaf to be at the site, It understands when you've pruned it. The plant thinks, "man we don't have much capacity to to do our solar photosynthesis so we need to push out a new set of leaves" and in that way it kind of forces a quick new growth and it bounces back healthier when you knock it down a little bit.

Gary - How often do you defoliate during a plants life cycle?

Gary - Just about everything we do to a plant we do to increase the yield. I would assume that is the same goal with defoliation. Since the end goal is to increase yield you must really believe in the technique.

Gary - Is everything below the screen kept clean? I know you use the P SCROG. How does defoliation work with the P SCROG?

Mike - Everything below the screen is clean for sure.

P SCROG Kits

or

SupportOurPlants@SCROGGER.com